If you're a business owner, you've probably encountered the following situations:

- A store reports a broken piece of equipment by phone — but where is the record? Who did the repair? What parts were used? It’s all unclear.

- Technicians say they took photos during installation or maintenance, but the images are scattered across Line chats or personal photo albums, making it impossible to consolidate.

- The company spends a lot on maintenance, yet there’s no data to analyze which parts fail the most or which stores report the most issues.

These challenges are common across industries — whether it’s coffee machines, water heaters, or beer taps. On the surface, everyone is doing “maintenance,” and the processes seem similar. But on closer inspection, each industry has its own pain points and unique requirements.

In this article, I’ll take FRESER INTERNATIONAL CORPORATION (a manufacturer of coffee machines and ice makers) as a starting point, then expand to the water heater and beer industries to explore how different sectors use digital systems to solve maintenance management challenges.

Case 1: Commercial Foodservice Equipment (Example: FRESER INTERNATIONAL CORPORATION)

FRESER INTERNATIONAL CORPORATION has long been a key player in the commercial foodservice equipment market, with a clear positioning: offering an all-in-one solution for essential store equipment. Its in-house product lines include post-mix cold beverage systems (e.g., soda, slush, granita, and cold drink dispensers), coffee and tea bar equipment (such as cup sealers, fructose dispensers, and extraction machines), hot food and combi oven solutions, as well as must-have items like water filtration/softening systems and refrigerated display units.

FRESER also represents several international brands, including fully automatic coffee machines (German and business-grade models), commercial water filtration systems, smart combi ovens, and ice makers. Through a hybrid strategy of in-house manufacturing, brand agency, and service integration, FRESER can cater to diverse business scales — from convenience stores and coffee chains to large-scale F&B brands.

Under the leadership of General Manager Chang Cui-Hsia, FRESER has moved beyond simply selling equipment — it has transformed maintenance and servicing into a source of valuable, analyzable service data. Every customer questionnaire, every technician check-in, every set of before-and-after photos, and every digital signature contributes to a feedback loop that enhances engineering quality, staff training, and product development.

In this way, maintenance is no longer just about "fixing a problem in the moment" — it becomes part of a trackable, comparable, and continuously improvable management cycle.

(Pictured: General Manager Chang Cui-Hsia of Hsing Jih Kuang)

"Maintenance is not a cost—it's a data asset. Every service request, every photo, and every signature is evidence that enables faster problem-solving the next time." — Ms. Chang Cui-Hsia, General Manager of FRESER INTERNATIONAL CORPORATION.

Traditionally, when equipment malfunctions, stores file a repair request and a technician is dispatched to resolve it. While there is often a “repair record,” stores themselves rarely retain this data, which makes long-term analysis impossible:

• Which parts break most frequently?

• Which equipment has a shorter lifespan?

• Is the issue with the product itself or user habits?

This is where the value of a system comes into play.

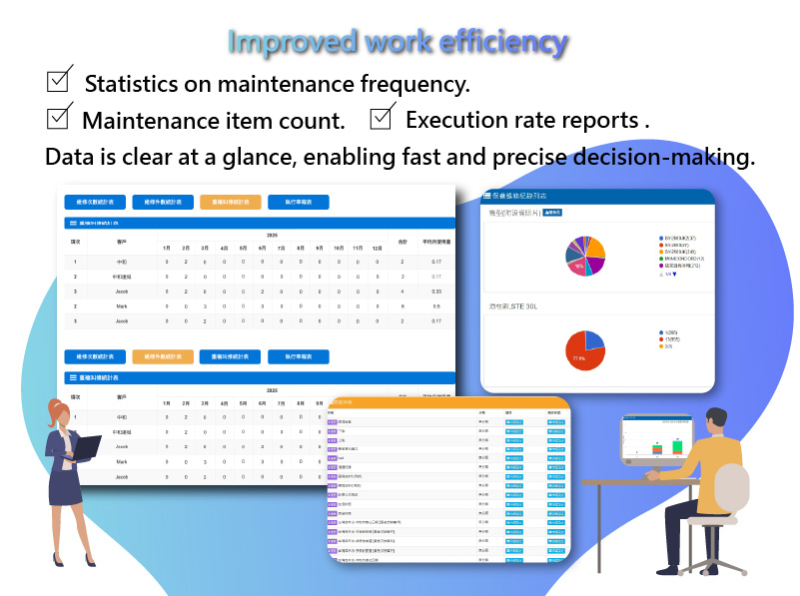

📌 With the SalesKing APP, FRESER is able to:

- Component lifespan analysis: Automatically consolidate which parts are most frequently replaced, aiding in backend design improvements.

- Maintenance quality monitoring: Customers provide feedback through questionnaires, allowing the system to assess technician performance.

- Custom reports: For example, statistics on repair frequency and repeated service requests help managers identify problematic stores and distinguish between misuse and part defects.

Image 1: Customized forms help businesses make informed decisions

Case 2: Water Heater Industry — Complete Workflow Management Before and After Installation

You might think installing or repairing a water heater is simple, but in reality, the process is quite complex:

- Sales visit: After receiving a request, sales personnel inspect the site, checking the water outlets and drains.

- Order placement and planning: Sales upload photos so technicians understand the site conditions and can prepare appropriate materials.

- Technician installation: Upon arrival, technicians take photos before and after installation to ensure all procedures meet standards.

Major challenges in this industry:

• Material management: Technicians often discover they’ve brought the wrong materials, requiring a second trip; companies also frequently face inventory discrepancies.

• On-site documentation: When disputes arise post-installation, there's often a lack of “evidence.”

📌 With the SalesKing APP, these issues are resolved:

• Inventory tracking: All parts carried by technicians are logged to improve warehouse management.

• Photo documentation: Images before and after installation are automatically uploaded to the system, minimizing disputes.

• Real-time updates: Supervisors can monitor job progress remotely, without waiting for technicians to return.

Image 2: Site assessments and pre/post installation photos ensure clarity and compliance

Case 3: Alcohol Industry (Beer Tap Maintenance)

Beer tap maintenance is especially unique, as beer taps are critical to beer sales, yet maintenance is often outsourced.

Key issues include:

• Did the external service personnel actually show up?

• How was the quality of their service?

• Are breakdowns more frequent with in-house or third-party branded taps?

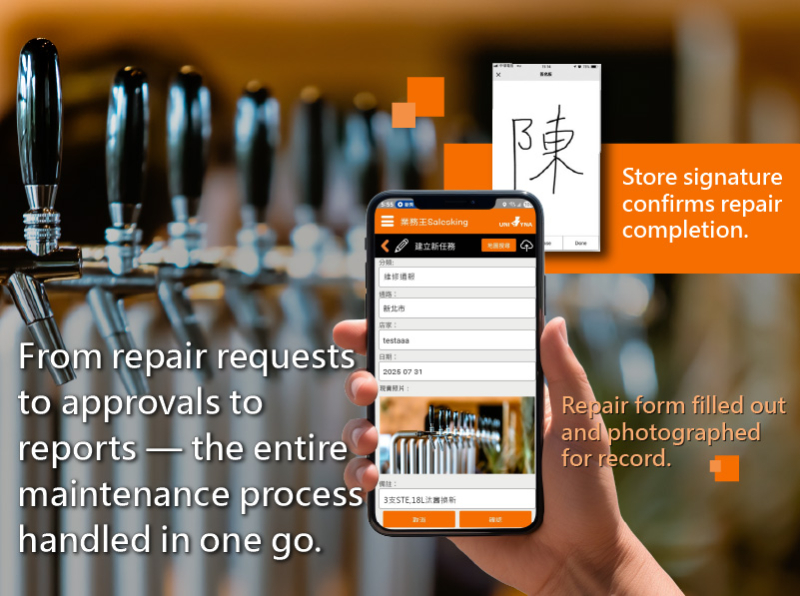

📌 With the SalesKing APP, breweries can:

- Monitor outsourced service quality: Technicians must upload photos and fill out repair forms via the app.

- Digitize service records: Combining surveys and photos ensures complete documentation.

- Brand maintenance stats: Easily distinguish between issues with owned versus third-party products, aiding procurement and service strategies.

Image 3: Digital signature feature allows store representatives to acknowledge repairs

Extended Thoughts: Different Industries, Different Pain Points, One Common Thread

Across these three cases:

• Coffee Machine Industry: Focus on part lifespan and service quality.

• Water Heater Industry: Focus on inventory tracking and installation verification.

• Alcohol Industry: Focus on outsourced personnel management and brand differentiation.

While all fall under the label of “maintenance,” the actual workflows differ drastically. This illustrates a key point:

👉 Digital transformation of maintenance must be customized by industry, not one-size-fits-all.

Why Is Customized Data Analysis So Important?

In the past, companies merely “kept records”—as long as they had a log, it was considered enough.

But in today's business climate, that’s no longer sufficient:

• If you only look at logs, all you know is how many times something was fixed.

• If you analyze the data, you can find out why things break, how to prevent them, and how to reduce costs.

This is the true value of digital reports. They help business owners move from reactive to proactive strategies.

Real-World Benefits: How the SalesKing APP Helps

To summarize, the SalesKing APP brings the following benefits to equipment maintenance:

- Data transparency: Beyond just “fixed or not,” it provides complete reports and defect rate analysis for products and components.

- Photo-based evidence: Ensures every install and repair is well-documented to avoid disputes.

- Feedback questionnaires: Quality control for both internal and outsourced personnel.

- Inventory management: Transparent usage of materials, reducing inventory pressure.

- Custom reporting: Generate daily, weekly, or monthly reports by industry or even by individual part.

Conclusion: Turn “Repair Records” Into “Strategic Intelligence”

Equipment maintenance management shouldn’t stop at fixing issues.

The real value lies in using records and data analysis to make better decisions.

For coffee machine makers, this means improving product design;

For the water heater industry, this means more efficient installations and happier customers;

For the alcohol industry, this means better control over outsourced services and lower maintenance costs.

All of this is made possible by the SalesKing APP.

Because digital transformation isn’t just about moving paper to a screen—it’s about turning records into insights, and reactions into strategy.

Notes (Sources):

• FRESER's commercial foodservice equipment and product portfolio (cold beverage dispensers, coffee/tea equipment, hot food solutions, display fridges, water filtration systems, etc.): Official product page | freser.com

• Fully automatic coffee machine brands (Melitta / KALERM): Official website and catalogs | freser.com

• BRITA commercial water filtration – Taiwan exclusive distributor: Official product page | freser.com